Product Description:

For protecting the hydraulic pump, it is recommended to install a surface type oil filter at the suction path of the pump. This oil filter should filter out larger impurities and particles. The filtration capacity of the oil filter must be more than twice the pump flow rate. The pressure loss should be less than 0.02 MPa.

An oil filter should be installed on the outlet oil circuit of the pump to filter out pollutants that may enter components such as valves. To ensure effective filtration, its filtration accuracy should be 10-15 μ m. It should also be able to withstand the working pressure and impact pressure on the oil circuit. The pressure drop of the oil filter should be less than 0.35 MPa, and a safety valve should be installed to prevent oil filter blockage.

The return oil line of the system should have a PALL filter element installed on it. This installation serves as an indirect filter. Usually, a back pressure valve is installed in parallel with the filter. When the filter becomes clogged and reaches a certain pressure value, the back pressure valve opens.

A PALL filter element is recommended to be installed on the system branch oil circuit. This ensures that even the smallest pollutants can be filtered out effectively.

Large hydraulic systems should be equipped with a dedicated hydraulic pump and oil filter to form an independent filtration circuit. Additionally, it is recommended to install a dedicated fine oil filter in front of some important components such as servo valves and precision throttle valves. This ensures their normal operation within the PALL filter hydraulic system.

Features:

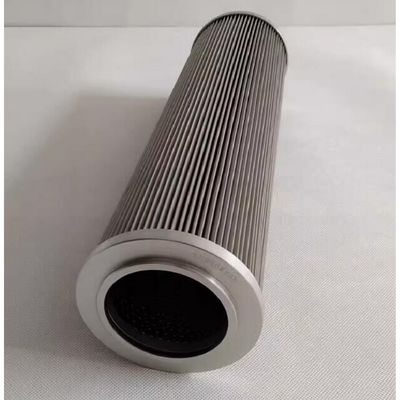

The Characteristics of PALL Filter Element

The PALL filter element is known for its exceptional features such as:

- Strong Hydrophobicity: PALL filter element has excellent hydrophobicity, which can effectively prevent moisture and other liquids from entering the system, protecting equipment from moisture damage.

- Large Filtration Area: The filter element uses high-efficiency filter materials such as to provide a large filtration area, which can efficiently filter impurities in liquids or gases.

- Strong Oil Permeability: The filter element design takes into account good oil permeability, and can maintain stable filtration performance even under high pressure and high flow conditions.

- Simple and Easy to Install Structure: The PALL filter element has a simple structural design that facilitates quick installation and replacement, reducing maintenance time and costs.

- Dense and Uniform Pore Size of Filter Element: The pore size distribution of the filter element is uniform and dense, which can efficiently intercept small particles and ensure filtration accuracy.

- High Filtration Efficiency: Due to the bridging phenomenon of particles in the filter pores, particles smaller than the pores can also be effectively blocked, and the filtration efficiency reaches over 98%.

- High Self-Cleaning: The filter material has high cleanliness, no pollution to water quality, and ensures the purity of the filtered liquid.

- Corrosion Resistant: The filter material has good chemical compatibility and can withstand corrosion from various strong acids, strong bases, and organic solvents.

- High Strength: The filter element can maintain its excellent physical strength by withstanding a pressure difference of 0.4mpa without deformation.

- Long Service Life and Low Cost: PALL filter has strong cleaning ability, long service life, low long-term use cost, and good economic benefits.

| HC2206FCT8Z |

HC2254FCN16Z |

HC6300FCS16H |

HC7500SCN8H |

| HC2207FCP3H |

HC2254FCS16Z |

HC6300FCT16H |

HC7500SCS8H |

| HC2207FCN3H |

HC2254FCT16Z |

HC6300FCP26H |

HC7500SCT8H |

| HC2207FCS3H |

HC2256FCP6H |

HC6300FCN26H |

HC7500SKJ8H |

| HC2207FCT3H |

HC2256FCN6H |

HC6300FCS26H |

HC7500SCP4H |

| HC2207FCP6H |

HC2256FCS6H |

HC6300FCT26H |

HC7500SCN4H |

| HC2207FCN6H |

HC2256FCT6H |

HC6300FCP8Z |

HC7500SCS4H |

| HC2207FCS6H |

HC2256FCP10H |

HC6300FCN8Z |

HC7500SCT4H |

| HC2207FCT6H |

HC2256FCN10H |

HC6300FCS8Z |

HC7500SDJ4H |

| HC2208FCP4H |

HC2256FCS10H |

HC6400FCP16Z |

HC7500SCP8H |

| HC2208FCN4H |

HC2256FCT10H |

HC6400FCN16Z |

HC7500SCN8H |

| HC2208FCS4H |

HC2256FCP6Z |

HC6400FCS16Z |

HC7500SCS8H |

| HC2208FCT4H |

HC2256FCN6Z |

HC6400FCT16Z |

HC7500SCT8H |

| HC2208FCP8H |

HC2256FCS6Z |

HC6400FCP26Z |

HC7500SDJ8H |

| HC2208FCN8H |

HC2256FCT6Z |

HC6400FCN26Z |

HC7500SCP4H |

| HC2208FCS8H |

HC2256FCP10Z |

HC6400FCS26Z |

HC7500SCN4H |

| HC2208FCT8H |

HC2256FCN10Z |

HC6400FCT26Z |

HC7500SCS4H |

| HC2216FCP4H |

HC2256FCS10Z |

HC6400FCP8H |

HC7500SCT4H |

| HC2216FCN4H |

HC2256FCT10Z |

HC6400FCN8H |

HC7500SUJ4H |

| HC2216FCS4H |

HC2257FCP6H |

HC6400FCS8H |

HC7500SCP8H |

| HC2216FCT4H |

HC2257FCN6H |

HC6400FCT8H |

HC7500SCN8H |

| HC2216FCP6H |

HC2257FCS6H |

HC6400FCP13H |

HC7500SCS8H |

| HC2216FCN6H |

HC6300FCS8Z |

HC6400FCN13H |

HC7500SCT8H |

| HC2216FCS6H |

HC6300FCT8Z |

HC6400FCS13H |

HC7500SUJ8H |

| HC2216FCT6H |

HC6300FCZ13Z |

HC6400FCT13H |

HC9601-FDS16H |

| HC2216FCP8H |

HC6300FCP13Z |

HC6400FCP16H |

PI-4208SMXVSTNR 77680515 |

| HC2216FCN8H |

HC6300FCN13Z |

HC6400FCN16H |

2.0004P10-A000P |

| HC2216FCS8H |

HC6300FCS13Z |

HC6400FCS16H |

852070SMX10NBR |

| HC2216FCT8H |

HC6300FCT13Z |

HC6400FCT26H |

LFAX-160X10 |

| HC2216FCP14H |

HC6300FCZ16Z |

HC6400FCP8Z |

TXW5-10 |

| HC2216FCN14H |

HC6300FCP16Z |

HC6400FCN8Z |

LF-0705 |

| HC2216FCS14H |

HC6300FCN16Z |

HC6400FCS8Z |

1.0095-G25-A00-0-P |

| HC2216FCT14H |

HC6300FCS16Z |

HC6400FCT8Z |

2.0030H20XL-A00-0-P |

| HC2216FCP4Z |

HC6300FCT16Z |

HC6400FCP13Z |

ARS610RA |

| HC2216FCN4Z |

HC6300FCZ26Z |

HC6400FCN13Z |

ZD-04-02150 |

| HC2216FCS4Z |

HC6300FCP26Z |

HC6400FCS13Z |

PI4130PS25 |

| HC2253FCT16Z |

HC6300FCN26Z |

HC6400FCT13Z |

18.80P10-C00-0-P |

| HC2254FCP8H |

HC6300FCS26Z |

HC6400FCP16Z |

PI9208DRGVST25 |

| HC2254FCN8H |

HC6300FCT26Z |

HC6400FCN16Z |

CU250M250V |

| HC2254FCS8H |

HC6300FCP8H |

HC6400FCS16Z |

MF4001A25HB |

| HC2254FCT8H |

HC6300FCN8H |

HC6400FCT16Z |

MF4002P25NB |

| HC2254FCP16H |

HC6300FCS8H |

HC6400FCP26Z |

PI25063DNSMX25 |

| HC2254FCN16H |

HC6300FCT8H |

HC6400FCN26Z |

PI4111PS25 |

| HC2254FCS16H |

HC6300FCP13H |

HC6400FCS26Z |

P-3501-2 10U |

| HC2254FCT16H |

HC6300FCN13H |

HC6400FCT26Z |

ZZLD250-0.2-1.6 |

| HC2254FCP8Z |

HC6300FCS13H |

HC7500SCS4H |

711823E1-301ETY6A |

| HC2254FCN8Z |

HC6300FCT13H |

HC7500SCT4H |

711823E1-301ETY369A |

| HC2254FCS8Z |

HC6300FCP16H |

HC7500SKJ4H |

R901025297250R10 |

| HC2254FCT8Z |

HC6300FCN16H |

HC7500SCP8H |

2.0250-H10XL-A00-0-M0 |

| HC2254FCP16Z |

|

|

|

Applications:

Petrochemicals

In the refining and chemical production processes, petrochemicals require separation and recovery of products and intermediate products to ensure purity. Additionally, liquids need to be purified for uses such as magnetic tapes, optical discs, and photographic films, as well as oil field well water and natural gas being filtered for particle removal.

Textile

Textile production requires the purification and uniform filtration of polyester melts during wire drawing processes. Air compressors used in the industry need protective filtration, and compressed gases require the removal of oil and water.

Electronics and Pharmaceuticals

Reverse osmosis and deionization are essential processes in electronics and pharmaceutical industries which require pre-treatment and filtration. The cleaning solution and glucose also demand purification for further treatment of the product.

Thermal Power and Nuclear Power

The lubrication systems, speed control systems, and bypass control systems of gas turbines and boilers require purification of oil. Feed pumps, fans, and dust removal systems also demand continuous filtration.

Mechanical Processing Equipment

Paper making machinery, mining machinery, injection molding machines, and large precision machinery rely on lubrication systems and compressed air purification. Additionally, tobacco processing equipment and spraying equipment require dust recovery and filtration.

Railway Internal Combustion Engines and Generators

For railway internal combustion engines and generators, filtration of lubricating oil and engine oil is critical to ensuring the reliability of the equipment.

Automotive Engines and Construction Machinery

Internal combustion engines, various hydraulic oil filters, diesel filters, and water filters for construction machinery need air, oil, fuel, and water filtration to operate efficiently and safely. Ships and heavy-duty vehicles also require these filters to maintain and increase their lifespan.

Support and Services:

Our Hydraulic Filter Element products come with comprehensive technical support and services to ensure that your filtration system is working at its best. Our team of experts are available to provide you with guidance on installation, maintenance, and troubleshooting. Additionally, we offer regular maintenance and cleaning services for your filter elements to ensure optimal performance and longevity.

Packing and Shipping:

The hydraulic filter element will be packaged in a sturdy cardboard box to ensure safe transportation and delivery to our customers. The box will be labeled with the product name, description, and any important handling instructions.

Shipping:

We offer free standard shipping within the United States for orders of the hydraulic filter element. Expedited shipping options are also available at an additional cost. We use reliable and trusted shipping carriers to ensure timely and safe delivery of our products. Customers will receive a tracking number once the order has shipped.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!