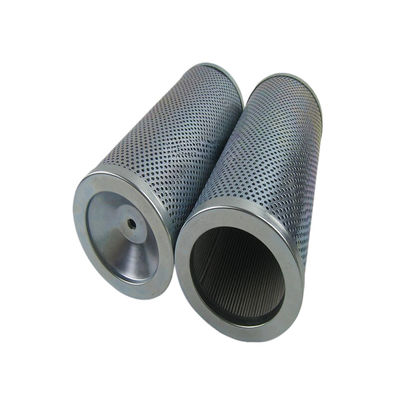

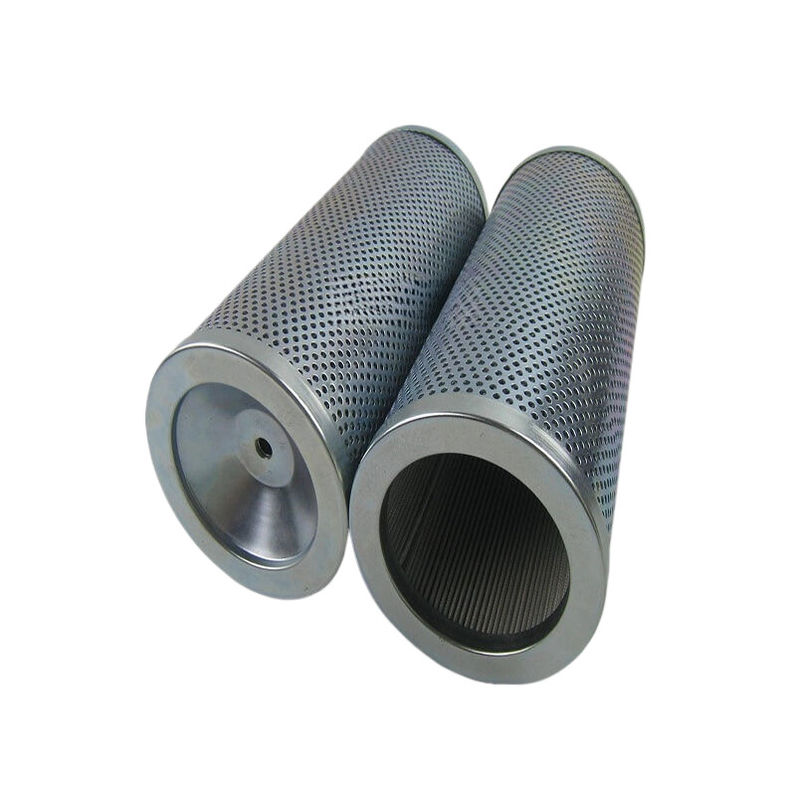

Product Description:

MP Filtri's Filter Elements Protect Hydraulic and Lubrication Systems

MP Filtri offers an extensive range of filter elements designed to safeguard hydraulic and lubrication systems against contamination and solid particulates. As particulate contamination remains the primary root cause of failures and malfunctions of these critical systems, it is essential to have an effective solution that ensures their optimal operation and longevity.

One of MP Filtri's product lines encompasses filter elements that are capable of protecting the systems from water ingress. This type of contamination can lead to the degradation of the lubrication capability and the surface protection provided by the fluid.

When it comes to controlling contamination within hydraulic and lubrication systems, mechanical processes are often the most effective method. MP Filtri's filter elements provide a mechanical solution that significantly reduces the risk of system failures and malfunctions caused by contamination.

Specifications:

Specifications:

| Part number |

FRTE100p10s-10-000 |

| Media |

Fiberglass |

| Filtration rate |

10μm |

| Out Diameter |

40.5mm |

| Length |

219.5mm |

| End cap |

Plastic |

| Skeleton |

Carton steel |

| Type |

Pleated |

| Usage |

Oil impurities |

Gasket material |

NBR |

Applications:

The machine tool industry heavily relies on hydraulic transmission and control, which is implemented in 85% of machine tool transmission systems. Grinding machines, milling machines, planers, lathes, presses, shearing machines, and combination machine tools all utilize hydraulic transmission and control to operate efficiently.

Hydraulic technology is equally important in the metallurgical industry, where it is used for electric furnace control systems, steel rolling mill control systems, open hearth loading, converter control, blast furnace control, strip deviation, and constant tension devices. This ensures that the steel production process is efficient and smooth.

Construction machinery relies on hydraulic transmission to function, with hydraulic technology being commonly used in excavators, tire loaders, truck cranes, track bulldozers, tire cranes, self-propelled loaders, graders, and vibratory rollers. These machines provide significant support in the construction and infrastructure development sector.

Agricultural machinery has not been left behind in utilizing hydraulic technology, with combine harvesters, tractors, and plows relying on hydraulic technology to achieve optimal efficiency in their operations.

Even in the automotive industry, hydraulic technology plays a key role. Hydraulic off-road vehicles, hydraulic dump trucks, hydraulic aerial work vehicles, and fire trucks all rely on hydraulic technology to function accurately. This ensures that these vehicles can operate safely and effectively in various terrains and conditions.

Last but not least, the textile industry uses hydraulic technology in plastic injection molding machines, rubber vulcanizing machines, paper machines, printing machines, and textile machines. Hydraulic technology is essential to ensure that these machines operate at peak performance and produce high-quality textiles and paper products.

Support and Services:

Our Hydraulic Filter Element product is designed to remove contaminants from hydraulic fluid and protect hydraulic components from damage. It is made of high-quality materials and is engineered to meet or exceed OEM specifications. We offer technical support and services to assist with installation, troubleshooting, and maintenance. Our team of experts is available to answer any questions and provide guidance on selecting the appropriate filter for your specific application. In addition, we offer filter element replacement services to ensure your hydraulic system remains operating at peak performance. Contact us for more information on our technical support and services for the Hydraulic Filter Element product.

Packing and Shipping:

Product Packaging:

- 1 Hydraulic Filter Element per box

- Box dimensions: 8" x 8" x 8"

- All boxes will be labeled with product information and handling instructions

Shipping:

- All orders will be shipped within 2 business days

- Shipping options include standard ground and expedited shipping

- Shipping rates will be calculated at checkout based on destination and selected shipping method

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!