Product Description:

MP Filtri's Filter Elements Protect Hydraulic and Lubrication Systems

MP Filtri produces top-quality filter elements designed to protect hydraulic and lubrication systems from the ill-effects of contamination and solid particulates.

In hydraulic and lubrication systems, particulate contamination is the root cause of failures and malfunctions. The problem is a serious one, affecting the smooth operation of these systems, which can quickly lead to downtime and other issues if not checked.

To address this issue, MP Filtri has designed a range of filter elements that can also protect against water ingress. Water ingress can be a particular problem for hydraulic and lubrication systems since it leads to degradation of the lubrication capability and the surface protection provided by the fluid.

The good news is that controlling contamination within these systems is usually achievable through mechanical processes, and MP Filtri filter elements offer some of the best protection available.

Specifications:

| Product |

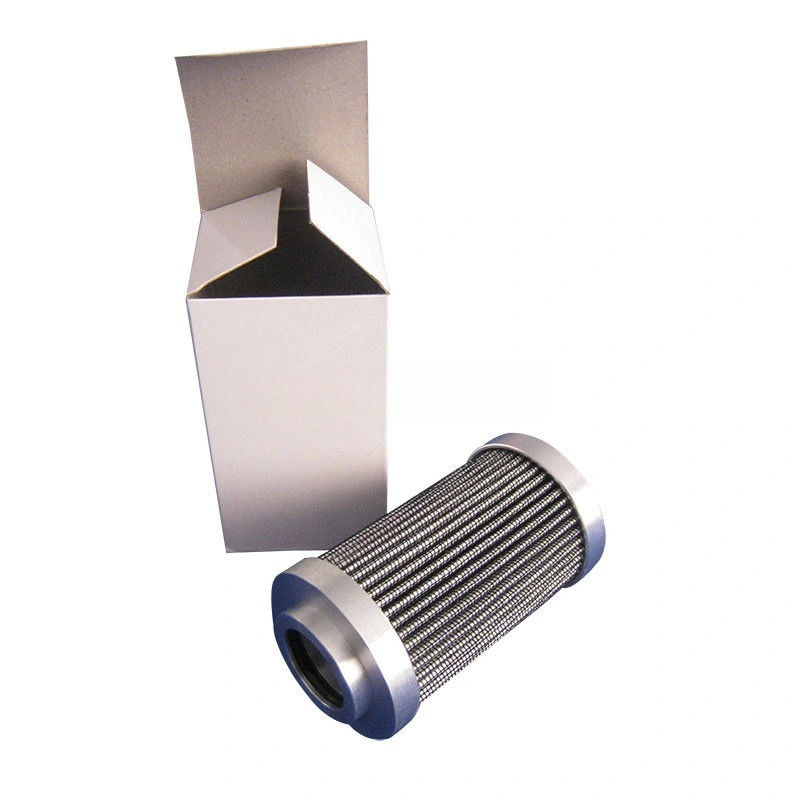

Equivalent MP FILTRI hydraulic Filter |

| Part Number |

MF1001 |

| Type |

Cartridge |

| Media |

stainless steel wire mesh |

| Out Diameter |

Please contact us |

| Length |

Please contact us |

| Micron |

10 |

Applications:

Hydraulic Technology Usage in Various Industries

The machine tool industry heavily relies on hydraulic transmission and control, with 85% of machine tool transmission systems using this technology. This includes machines such as grinding machines, milling machines, planers, lathes, presses, shearing machines, and combination machine tools.

In the metallurgical industry, hydraulic technology is commonly used in a variety of applications such as electric furnace control systems, steel rolling mill control systems, open hearth loading, converter control, blast furnace control, strip deviation, and constant tension devices.

Construction machinery such as excavators, tire loaders, truck cranes, track bulldozers, tire cranes, self-propelled loaders, graders, and vibratory rollers all commonly use hydraulic transmission in their operations.

Agricultural machinery also widely uses hydraulic technology in machines like combine harvesters, tractors, and plows.

The automotive industry also incorporates hydraulic technology, particularly in off-road vehicles, dump trucks, and aerial work vehicles. Even fire trucks use hydraulic technology in their operations.

Finally, the textile industry also relies on hydraulic technology in machines such as plastic injection molding machines, rubber vulcanizing machines, paper machines, printing machines, and textile machines.

Support and Services:

The Hydraulic Filter Element is designed to remove contaminants from hydraulic fluids, lubricants and oils. It is made of high-quality materials and features a pleated filter media that provides excellent filtration efficiency and dirt-holding capacity. The filter element is compatible with a wide range of hydraulic systems and is easy to install and replace.

Our technical support team is available to help you with any questions or issues you may have regarding the Hydraulic Filter Element. We can assist you with product selection, installation, maintenance, and troubleshooting. We also offer a range of services to help you get the most out of your filter element, including filter element testing and analysis, predictive maintenance, and training.

With our technical support and services, you can be confident that your Hydraulic Filter Element is working at its best and protecting your hydraulic system from contamination and damage.

Packing and Shipping:

Product Packaging:

- The hydraulic filter element will be packaged in a sturdy cardboard box.

- The box will be labeled with the product name, quantity, and any necessary safety information.

- The filter element will be securely wrapped in bubble wrap and/or packing peanuts to prevent any damage during shipping.

Shipping:

- The hydraulic filter element will be shipped via a reputable carrier, such as UPS or FedEx.

- The shipping method will be chosen based on the customer's preference and the urgency of the order.

- The customer will be provided with a tracking number so they can monitor the status of their shipment.

- The estimated delivery date will be communicated to the customer at the time of purchase.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!