Product Description:

Product structure and principle related attributes

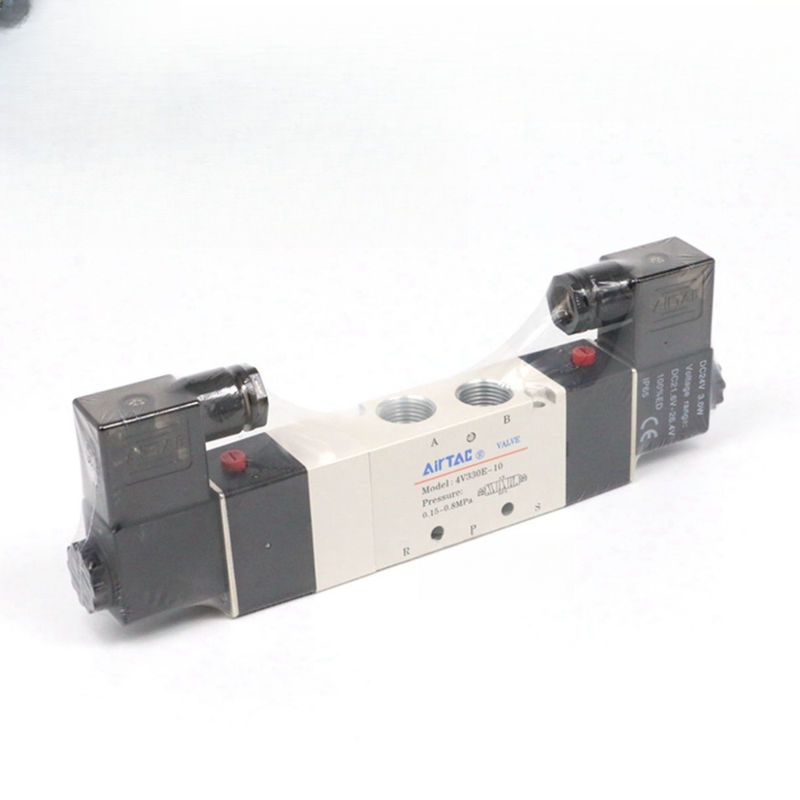

Pilot mode: There are internal or external guidance options available, which can be selected according to actual application scenarios and needs.

Action modes: Mainly including direct action and pilot action. The direct acting type relies on electromagnetic force to directly drive the valve core action, with a simple structure and no need for medium pressure assistance. It is suitable for low flow and low pressure drop scenarios and has a fast response speed; The pilot type uses the pilot air path to control the action of the main valve core, requiring a certain medium pressure difference to work, suitable for high flow and high pressure difference scenarios, with low power consumption.

Sliding column structure: Good sealing, sensitive response, able to quickly and accurately achieve the on/off and switching of gas paths.

Number of valve positions: There are various types such as two position three-way, two position five way, and three position five way to meet different pneumatic control circuit requirements.

Memory function: The dual head two position solenoid valve has a memory function, which can maintain the previous state after power failure, helping the system to operate stably.

Product performance related attributes

Working pressure range: Generally 0.15-0.8MPa, different models may vary, and can adapt to various pneumatic systems with different pressure requirements.

Temperature range: Usually -20 ℃ to 70 ℃, special models support a wider range and can work normally at different ambient temperatures.

Response time: Short, usually in milliseconds, can quickly switch gas paths and improve system efficiency.

Switching frequency: High, able to meet the working requirements of frequent actions, suitable for fast cycling pneumatic control processes.

Power consumption: Low power design, energy-saving and reducing heat generation, helps to reduce system operating costs and improve safety.

Product material and specification related attributes

Valve body material: Made of aluminum alloy or stainless steel, it has strong corrosion resistance and can adapt to different working environments, such as humid, acidic and alkaline corrosive environments.

Sealing material: Mostly NBR (nitrile rubber) or FKM (fluororubber), can adapt to different media such as air, inert gases, etc., ensuring good sealing performance.

Nominal diameter: Common sizes include DN50mm - DN300mm (NPS2-12), as well as interface sizes such as 1/8 ", 1/4", and 3/8 ", which can meet different flow requirements and pipeline connection requirements.

Voltage: Multiple standard voltage levels such as DC12V/24V, AC110V/220V are available for selection, making it convenient to match with different electrical control systems.

Product features and application related attributes

Function type: There are normally open (NO), normally closed (NC), bidirectional control, etc., and the appropriate function type can be selected according to specific control requirements.

Application areas: Widely used in industries such as packaging, papermaking, printing, electrical, biotechnology, petroleum, energy, electronics/batteries, as well as pneumatic control circuits in automation control systems.

Product protection related attributes: The standard product protection level reaches IP65, dustproof and waterproof, suitable for harsh industrial environments, can effectively protect the internal components of the solenoid valve from external dust and moisture erosion, and improve the reliability and service life of the product.

Technical Parameters:

-

Multiple Control Modes

- Normally Closed/Normally Open Types: The valve port is closed or open in the default state, suitable for scenarios requiring a safe initial state (such as emergency shutdown or automatic air supply).

- Bidirectional Control Type (e.g., 2-position 5-way or 3-position 5-way valves): Supports bidirectional air flow switching, used to drive cylinder reciprocating motion (such as the extension and retraction of mechanical arms or the start and stop of conveyor belts).

- Memory Function Type: Maintains the valve position after power failure to prevent system out-of-control due to power loss (such as process maintenance in continuous production lines).

-

Flow and Pressure Regulation

- Wide Range of Nominal Diameters: From small calibers (e.g., G1/8") to large sizes (e.g., DN50mm), adapting to different flow requirements (small flow for precision instruments, large flow for industrial equipment).

- Broad Pressure Range: The working pressure typically ranges from 0.15 to 0.8MPa, compatible with low-pressure pneumatic systems (such as automated production lines) and medium-to-high-pressure scenarios (such as construction machinery and heavy equipment).

AirTAC solenoid valves are widely used in industries with high automation and precise pneumatic control requirements. Typical application scenarios include:

| Industry |

Examples of Application Scenarios |

| Manufacturing |

Pneumatic positioning of machine tool fixtures, grabbing by robotic arms on assembly lines, and paint conveying control for spraying equipment. |

| Packaging & Printing |

Pneumatic control of bag mouth heat sealing in packaging machines, paper conveying and tension adjustment in printing machines, and folding action drive in carton pasting machines. |

| Food & Pharmaceutical |

Aseptic pneumatic control for food processing equipment (e.g., filling machines, sealing machines), and clean air source switching for pharmaceutical production lines (requiring corrosion-resistant seals). |

| Electronics/Semiconductor |

Vacuum adsorption control in semiconductor packaging equipment, pneumatic gripper actions in electronic component plug-in machines, and liquid injection valve control in lithium battery production lines. |

| New Energy |

Pneumatic handling devices in photovoltaic module production lines, hydraulic pilot control for wind power equipment, and gas pipeline switching for energy storage devices. |

| Construction Machinery |

Hydraulic pilot control for excavators/loaders, pneumatic braking systems for cranes, and pneumatic spray valve control for agricultural machinery. |

| Environmental Protection & Water Treatment |

Pneumatic valve switching in wastewater treatment plants (e.g., aeration tanks, sedimentation tanks), and gas diversion for waste gas treatment equipment. |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!