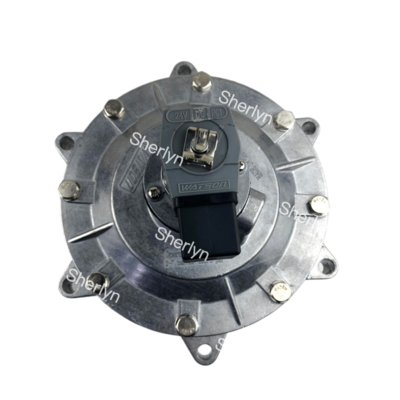

Detailed Product Description

| Model Number: |

WPS-CA/EP76 |

Make: |

WATSON |

| Body Material: |

Aluminium Alloy |

Diaphragm Kit: |

WPS-CA/EP76 Diaphragm |

| Coil: |

DC24V AC220V |

Protection Class: |

IP65 With Cable Plug |

| Highlight: |

pulse solenoid valve

,

pulse jet valve

|

Product Description:

Structural Design and Durability:

The valve body is often made of high-purity aluminum alloy die-casting, ensuring the strength and corrosion resistance of the valve body. The core component diaphragm uses special rubber materials such as nitrile rubber. These materials have high tensile strength, excellent aging resistance, and low wear, thus ensuring the long life of the diaphragm. It is claimed that the injection life can reach more than 1 million times, and even have a stable performance of three to five years without damage.

High Performance Coils and Protection:

The electromagnetic coil adopts all copper enameled wire and has undergone insulation sealing treatment with IP65 protection level. This makes the coil have good dust and water resistance, and can adapt to harsh industrial environments. The coil design is very user-friendly and can rotate 360 ° on the valve core. The junction box also supports 4 x 90 ° rotation installation. This greatly facilitates installation requirements from different angles and spaces, and effectively prevents rainwater from entering.

Working Principle and Response Characteristics:

The valve adopts the electromagnetic pilot working principle. When an electrical signal is input, the electromagnetic armature attracts and opens the pressure relief hole, causing the diaphragm to quickly lift up for spraying. After the electrical signal disappears, the armature resets and closes the pressure relief hole, and the diaphragm closes to stop blowing. This mechanism ensures fast response and reliable action of the valve. There are throttling holes designed on the diaphragm, which play a role in balancing the airflow during the pressure relief process and help the diaphragm to quickly close.

Environmental Adaptability:

The product can adapt to a wide temperature range. Depending on the membrane material, the normal temperature type membrane is suitable for temperatures ranging from -25 ℃ to 85 ℃, while the high temperature type membrane can even withstand high temperatures ranging from -25 ℃ to 230 ℃ (specific models need to be confirmed). The working medium is required to be clean air, with a relative humidity typically not exceeding 85%.

Applications:

Application Fields: Specific Application Scenarios, Functions, and Importance

The bag filter dust removal system (core application) serves as the "compressed air switch" for dust collectors in industries such as power, cement, metallurgy, chemical, and waste treatment. It sprays and cleans the filter bags in an orderly manner according to control signals, ensuring efficient and stable operation of the dust collector and meeting emission standards.

Material recycling and pneumatic conveying in pharmaceuticals, food processing, pigment production, and other processes that require the recycling of expensive products or the maintenance of clean production environments effectively separate and collect dust, reduce material loss, and improve recovery rates.

Industrial automation and process control. Automation control systems in industries such as petroleum, chemical, pharmaceutical, and food work together with other sensors and actuators to achieve rapid fluid switching and control, meeting the needs of automated production.

WATSON Solenoid Valve WPS-CA/EP76 Submerged Type Pulse Jet Valve AC220V DC24V

Technical Specifications:

(1). Working Pressure: 4-6 bar;

(2). Working medium: clean air

(3). Power supply: DC24V (AC220V/50Hz- 240V/60Hz)

(4). Class of protection: IP65;

(5). Working environment:

Normal-temperature diaphragm: -20OC- 80O C;

High-temperature diaphragm: 55℃ -180℃

The relative humidity of air is no more than 85%

| Construction |

| Body |

Aluminum |

| Core tube |

Stainless steel |

| Core and Plugnut |

Stainless steel |

| Core Spring |

Stainless steel |

| Sealing & disc |

CR (chloroprene) |

| Diaphragm |

NBR(nitrile/buna-n) |

| Shading coil |

Copper |

| Connector |

DIN43650A |

| Voltage |

DC: 24V, AC: 24V,48V,110V,230V |

| Working Temperature |

-20 to +85℃ |

| Protection Class |

IP65 |

| Coil Insulation Class |

F |

| Working Pressure |

0.35-0.85Mpa |

Support and Services:

Our Product Technical Support and Services team for the Pulse Jet Valves product is dedicated to assisting customers with any technical issues or questions they may have. Our knowledgeable experts can provide troubleshooting guidance, product specifications, installation assistance, and maintenance tips to ensure the optimal performance of your Pulse Jet Valves.

Packing and Shipping:

Product Packaging:

The Pulse Jet Valves are carefully packaged in a sturdy cardboard box to ensure safe delivery. Each valve is wrapped in protective foam to prevent any damage during transportation.

Shipping:

Orders for Pulse Jet Valves are shipped using a reliable courier service to ensure timely delivery. Customers can track their shipment using the provided tracking number to know the status of their order.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!