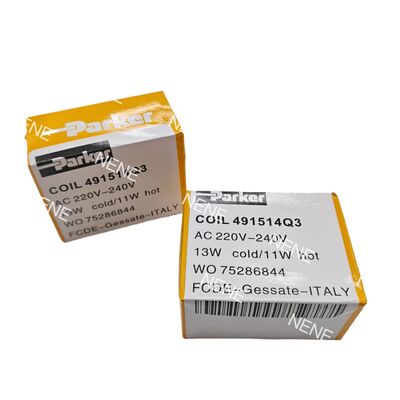

Product Description:

The Parker 32mm Solenoid Coil represents a complete lineup of driving units specifically crafted for the high-performance FCSE series of threaded cartridge solenoid valves. Known for their sturdy build quality, outstanding electromagnetic efficiency, and adherence to international standards, this series is tailored to accommodate a wide range of applications. These range from typical factory automation tasks to more challenging environments in industrial and process control settings.

Each solenoid coil is carefully engineered to ensure precise mechanical and electrical compatibility with FCSE valve bodies. This careful design guarantees efficient power transmission and swift operational response. At the heart of the coil’s design lies an internal polar expansion technology, which enhances the magnetic field efficiency. This ensures consistent high performance while effectively minimizing heat accumulation issues that can arise from voltage variations or extended use.

Features:

Global Market Access — Authoritative Multi-Certifications

This product series has achieved significant international safety certifications, including UL, CSA, and VDE. These certifications are crucial for entering high-end markets in North America, Europe, and other regions worldwide. They ensure the products comply with stringent safety regulations, electrical performance criteria, and environmental standards.

Beyond these, the products also adhere to important regional regulatory requirements such as CE, UKCA, and EAC. This compliance facilitates seamless global distribution and usage, overcoming regulatory challenges in various markets.

Excellent Electrical and Thermal Performance

Featuring high efficiency and low power consumption, the products utilize an optimized electromagnetic design combined with a Class H (180°C) insulation system. This enables a strong magnetic force while keeping temperature increases and energy usage minimal, thus enhancing long-term operational reliability.

Furthermore, the devices are engineered to operate across a broad temperature range, for instance from -40°C to +50°C. This wide range allows them to perform reliably in challenging conditions, including cold starts and continuous operation in hot environments such as workshops.

Flexible and Diverse Connection Options

Offering a comprehensive product range, various electrical interfaces and connection methods are available to accommodate different control cabinet configurations and field wiring needs. Options include standard flying leads, industrial connectors like the DIN 43650 type, among others, allowing customers to select the most suitable setup.

This versatility simplifies system integration, maintenance activities, and the replacement of spare parts, thereby enhancing overall user convenience.

Rugged and Reliable Design

The entirely encapsulated construction ensures excellent sealing, effectively protecting the internal components from exposure to oil, coolant, dust, and moisture. This robust design guarantees consistent and stable performance even in demanding industrial environments.

Technical Parameters:

| Coil Power Consumption |

12W |

| Mounting Dimension |

32mm |

| Electrical Connection |

2 P + E Plug According To EN 175301-803 Type A |

| Insulation Class |

H 180 °C |

| Coil Temperature Range |

-40°C to +50°C |

| Coil Specifications Met |

CE - VDE - UL - EAC |

Applications:

Renowned for their reliability, exceptional performance, and worldwide certifications, Parker 32mm FCSE coils have become a preferred choice across various industries.

In the field of industrial automation, these coils are extensively utilized in CNC machine tools, injection molding machines, robotic welding cells, and automated assembly lines, ensuring smooth and efficient operations.

They also play a crucial role in process control applications, managing fluid control systems in sectors such as chemical manufacturing, oil and gas, and water treatment facilities, where precision and durability are essential.

Moreover, Parker 32mm FCSE coils are integral to mobile machinery, particularly in hydraulic pilot control systems used in construction and agricultural equipment, providing reliable control under demanding conditions.

Additionally, they are employed in test equipment, powering high-precision instruments including material testing machines and fatigue test benches, where accurate and consistent performance is critical.

Support and Services:

Our Pneumatic Solenoid Valve product is designed to deliver reliable and efficient performance in various industrial applications. For any technical support or service inquiries, our team of experts is available to assist you with installation guidance, troubleshooting, maintenance advice, and replacement parts information.

We recommend regular inspection and cleaning of the valve to ensure optimal functionality and to prevent any potential operational issues. Detailed product manuals and datasheets are available to provide comprehensive information on specifications, wiring diagrams, and operational procedures.

If you experience any performance issues or require technical assistance, please have your product model number and purchase information ready to facilitate prompt support. Our service team is committed to resolving your issues quickly to minimize downtime and maintain your system's efficiency.

For maintenance services, we offer calibration, repair, and replacement options to extend the lifespan of your Pneumatic Solenoid Valve. Utilizing genuine parts and following recommended service intervals will help maintain the valve's reliability and safety standards.

We also provide training resources and technical webinars to help users better understand the product features and best practices for installation and operation. Stay updated with the latest product enhancements and software updates through our support portal.

Packing and Shipping:

Product Packaging and Shipping

The Pneumatic Solenoid Valve is carefully packaged to ensure it arrives in perfect condition. Each valve is individually packed in anti-static foam and sealed within a sturdy cardboard box to protect against impact and environmental factors during transit.

Multiple units are then placed in a larger, reinforced carton with additional padding to prevent movement. All packages are clearly labeled with product information, handling instructions, and shipping details to facilitate smooth delivery.

We offer various shipping options including standard ground, expedited, and international shipping. Our logistics partners ensure timely and safe delivery to your specified destination.

For bulk orders or special requirements, customized packaging solutions are available upon request to meet your specific needs.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!