Product Description:

I. Core Material Properties

The material of the pulse valve diaphragm is crucial for its performance. Dahe pulse valve diaphragms predominantly utilize elastomer materials. Common types and their characteristics include:

Advantages: Good oil resistance, suitable for conditions with oil mist; moderate elasticity and low cost.

Limitations: General temperature resistance (-20℃ to 120℃), weak ozone aging resistance.

Advantages: Excellent high and low temperature resistance (-20℃ to above 200℃), strong resistance to chemical corrosion, ozone, and aging. Suitable for high-temperature and corrosive working conditions.

Limitations: Higher cost, slightly lower elasticity than nitrile rubber.

Advantages: Good weather and ozone resistance, resistant to water vapor and weak acid corrosion. Applicable to a wide temperature range (-40℃ to 150℃).

Limitations: Poor oil resistance, not suitable for oil-containing environments.

- Nitrile Butadiene Rubber (NBR):

- Fluoroelastomer (FKM):

- Ethylene Propylene Diene Monomer (EPDM):

Some high-end models may incorporate composite materials (e.g., rubber combined with fabric skeleton) to enhance tear resistance and strength.

II. Physical and Mechanical Properties

Elasticity and Resilience: The diaphragm requires high elasticity and resilience to open and close quickly under high-frequency pulse airflow.

Tensile Strength and Tear Strength: Essential for withstanding tensile forces and preventing rupture or damage.

Hardness: Materials with Shore hardness of 60-80A are typically used to balance sealing effectiveness and response speed.

Temperature Resistance: Matching the material to the working temperature is vital for optimal functionality.

III. Working Characteristics

Sealing Performance: Precise processing of the fitting surface ensures complete sealing to prevent air leakage and maintain efficiency.

Response Speed: Quick opening and closing are necessary for efficient air flow and minimal jet time.

Medium Resistance: Resistance to moisture, oil stains, and dust particles is crucial for long-term durability and performance.

Technical Parameters:

| Conventional nitrile rubber (NBR) |

-20 ℃~80 ℃, Suitable For Room Temperature Drying Conditions |

| Working pressure range |

0.4-0.7MPa |

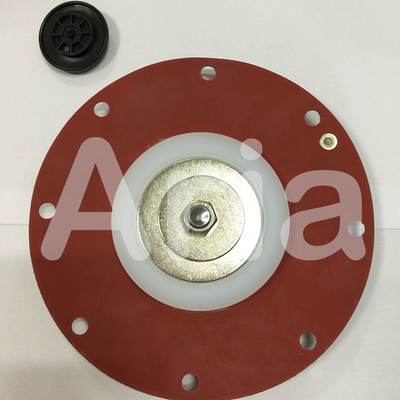

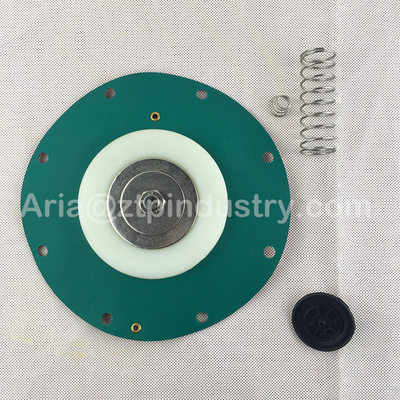

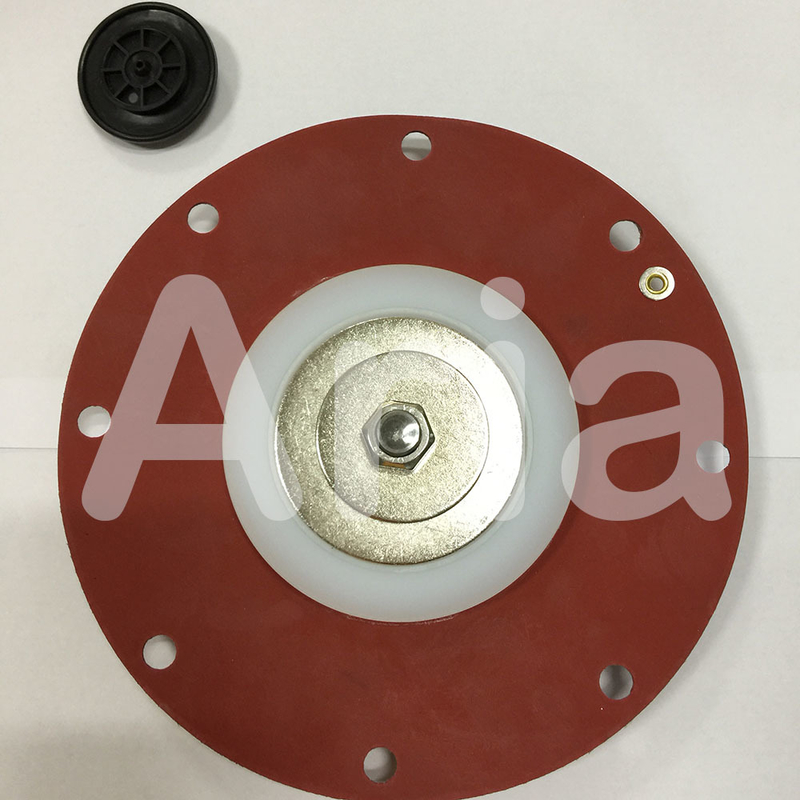

| Color |

Red Green Black |

| Brand |

TAEHA |

| Diaphragm Material |

NBR |

| Fluororubber (FKM) |

-20 ℃~200 ℃ (some Models Can Reach 260 ℃), Suitable For High Temperature And Corrosive Environments (such As Chemical And Waste Incineration) |

| Model |

Pipe Size |

Connection |

Cv Factor |

Weight |

Applications:

Working Condition Adaptation

The material used for diaphragms is selected based on the temperature of the dust removal system, the type of medium (oil-containing, corrosive gas, etc.), and the pulse pressure (usually 0.2~0.6MPa).

For example:

- Corrosive environments such as waste incineration plants and chemical workshops → fluororubber diaphragms;

- Normal temperature and non-corrosive environments such as wood processing and grain processing → nitrile rubber diaphragms.

Service Life

Under normal working conditions, high-quality diaphragms can last for 100,000~300,000 pulse cycles (about 1~3 years), depending on factors such as material, working temperature, pulse frequency, and maintenance conditions.

Improper maintenance, such as excessive moisture in compressed air causing accelerated aging of the diaphragm, can significantly reduce its service life.

In conclusion, the core properties of Dahe pulse valve diaphragms include high elasticity, strong sealing, fatigue resistance, and strong adaptability. The performance of these diaphragms directly impacts the stable operation of pulse valves and the overall dust removal system.

When selecting diaphragms, it is essential to consider the material, size, and mechanical properties in conjunction with the specific working conditions.

Packing and Shipping:

Product Packaging:

The Pulse Valve Diaphragm is carefully packaged to ensure its safe delivery. It is wrapped in protective material to prevent any damage during transit. The product is then placed in a sturdy cardboard box with appropriate cushioning to minimize the risk of breakage.

Shipping:

Once the Pulse Valve Diaphragm is securely packaged, it is ready for shipping. We partner with reliable shipping carriers to ensure timely delivery to our customers. You will receive a tracking number so you can monitor the progress of your shipment. Our priority is to get the product to you in the best condition possible.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!