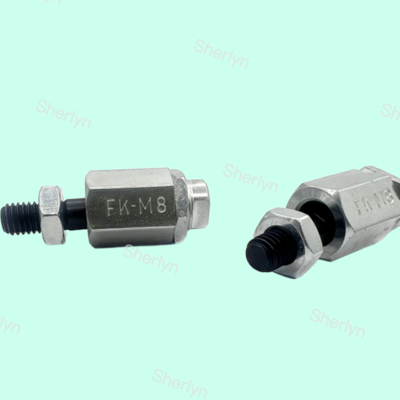

Product Description:

The main function of the FESTO FK series floating joint is to connect the cylinder piston rod with the driven load. It can automatically compensate for possible radial offset and angular deviation (usually up to ± 0.3mm to ± 0.7mm, or about 1mm) during the connection process. This compensation capability can effectively reduce stress, prevent problems such as piston rod seal wear and cylinder damage caused by poor alignment, and thus extend the service life of the entire pneumatic system.

This series of joints is usually made of sturdy materials such as galvanized steel, stainless steel, or surface hardened steel components, and treated with nickel plating to give them moderate to good corrosion resistance, which can adapt to general industrial environments and even situations with certain corrosion risks.

The FK series floating joint design does not contain copper (with copper content exceeding 1% by mass) or PTFE (polytetrafluoroethylene), which makes it suitable for applications that are sensitive to copper ions and specific chemicals, such as certain chemical processes or situations where copper materials prevent electrochemical corrosion.

Its working temperature range is wide, usually between -40 °C and +150 °C, which means it can maintain stable performance in both cold and low-temperature environments as well as high-temperature workshops. FK connectors offer multiple thread specifications (such as M10x1.25, M16x1.5, M20x1.5, etc.) to meet the needs of different sizes of cylinder piston rod threads and load connection ends.

Applications:

FESTO FK series floating joints are extensively employed in various industrial automation sectors. They play a crucial role in scenarios involving cylinder usage where there exists a certain degree of installation error or the necessity to compensate for eccentricity.

Industrial automation and pneumatic systems: The FK series joints find their most common application in connecting the cylinder piston rod with loads requiring cylinder propulsion, like fixtures, robotic arms, conveyor belt baffles, and flipping mechanisms. They ensure smooth cylinder operation and prevent jamming, even in cases of slight parallelism or coaxiality errors between the cylinder and load mounting base.

Lithium ion battery production and assembly: Specifically suited for lithium ion battery production and assembly, FK joints support high-precision manufacturing processes by enhancing equipment stability and reliability. They aid in error compensation, facilitating smooth production operations.

Precision equipment with high alignment requirements: FK floating joints are beneficial for equipment demanding precise positioning and repeatability. By eliminating internal forces resulting from processing and assembly errors, these joints enhance movement fluidity and positioning accuracy.

Thermal expansion or vibration scenarios: When equipment experiences thermal expansions or contractions due to temperature fluctuations or slight vibrations from motion, FK joints' floating capability absorbs these small displacement changes, ensuring reliable connections.

Medium corrosive environments: Featuring corrosion-resistant materials, FK joints can operate in environments posing a certain corrosion risk where not all stainless steel joints are necessary. These environments include specific chemical, food processing, or humid industrial settings.

Support and Services:

Our Product Technical Support team for Pneumatic Pipe Fittings is dedicated to providing assistance with installation, troubleshooting, and maintenance of our products. Our experts are available to answer any technical questions and offer guidance to ensure the proper functioning of your pneumatic system.

In addition to technical support, we also offer a range of services for Pneumatic Pipe Fittings, including installation services, training workshops, and customized solutions to meet specific requirements. Our goal is to help you maximize the performance and efficiency of your pneumatic systems.

Packing and Shipping:

Product Packaging:

The pneumatic pipe fittings will be securely packaged in a sturdy cardboard box to ensure safe delivery.

Shipping:

We offer fast and reliable shipping services for our pneumatic pipe fittings. Once your order is placed, we will process it promptly and ship it to your provided address. You can expect your product to arrive within the specified delivery timeframe.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!