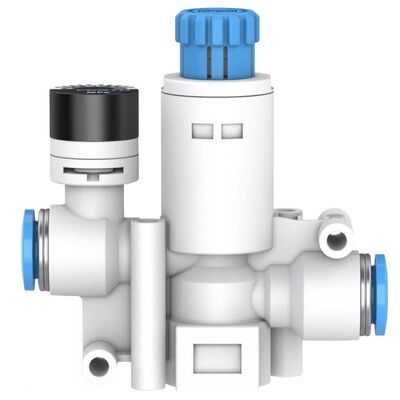

- Controller functionOutlet pressure constant With secondary exhausting With return flow function

- Pneumatic connection 1QS-8

- Pneumatic connection 2QS-8

- Type of mountingWith through-hole

- Normal nominal flow rate (normalized to DIN 1343)125 l/min

- Ambient temperature0 °C ... 60 °C

- Housing materialPBT

- Operating mediumCompressed air as per ISO 8573-1:2010 [7:4:4]

Product Description:

Accurate Pressure Control and Consistent Performance

The device employs a piston-type regulating mechanism that efficiently compensates for fluctuations in inlet pressure. This ensures that the outlet pressure remains steady at the preset level. High-precision variants, such as the VRPA-CM model, achieve an impressive regulation accuracy of ±1%, making them ideal for applications requiring sensitive pneumatic pressure stability.

Space-Efficient Design with Durable Build

Designed with compactness in mind, this product can be installed directly inline within tubing systems or mounted conveniently on valve manifolds. The main body is constructed from PBT engineering plastic, which provides a lightweight yet sturdy framework, perfectly balancing strength and reduced mass.

Built-in Functionalities and Energy Conservation

Equipped with a standard secondary exhaust feature, it swiftly releases excess downstream air whenever pressure is lowered. Additionally, an integrated bypass function allows reverse airflow under certain conditions, increasing the system’s adaptability. By supplying pressure only as needed, the device helps minimize compressed air usage, thereby promoting energy efficiency.

Applications:

The VRPA series is highly regarded for its stability and compact design, making it a popular choice in various industries.

In the realm of general industrial automation, the VRPA series plays a crucial role by maintaining stable working pressure for a range of components including cylinders, small pneumatic grippers, and assembly tools. This functionality makes it an essential part of the air preparation systems used on automated production lines.

When it comes to precision machining and testing, the VRPA series stands out due to its high accuracy and rapid response time. These qualities are vital for applications that rely on precise pressure control, such as pneumatic gauging, material testing devices, and precision dispensing control systems.

Additionally, the compact size of the VRPA series allows it to be easily integrated into equipment where space is at a premium. This includes applications like industrial robot arms and modular pneumatic stations. Moreover, some models within the series are designed to meet the stringent requirements of cleanroom environments, further expanding their versatility.

Support and Services:

Festo offers comprehensive technical support and services for its solenoid valve products to ensure optimal performance and reliability. Our support includes detailed product documentation, installation guides, and troubleshooting manuals to assist users in the proper setup and maintenance of solenoid valves.

Customers can access online resources such as FAQs, instructional videos, and software tools designed to facilitate configuration and diagnostics. Festo’s team of technical experts is available to provide consultation on product selection, application engineering, and system integration to meet specific operational requirements.

In addition, Festo provides repair and maintenance services to extend the lifespan of solenoid valves, including replacement parts and refurbishment options. Training programs and workshops are also offered to enhance user knowledge and ensure safe and efficient handling of the products.

By leveraging Festo’s technical support and services, users can maximize the efficiency, durability, and functionality of their solenoid valve installations across various industrial applications.

Packing and Shipping:

Product Packaging: The Festo Solenoid Valve is carefully packaged to ensure safe delivery and optimal protection during transit. Each valve is individually sealed in anti-static bags to prevent moisture and dust exposure. The sealed product is then placed in a sturdy, custom-fitted cardboard box with protective foam inserts to minimize movement and impact. The packaging includes a detailed product label with specifications, model number, and barcode for easy identification and inventory management.

Shipping: Festo Solenoid Valves are shipped using reliable logistics partners to guarantee timely and secure delivery worldwide. The packages are handled with care and tracked throughout the shipping process. Shipping options include standard, expedited, and express services to meet customer requirements. All shipments comply with international shipping regulations and include necessary documentation such as commercial invoices, packing lists, and certificates of origin when required.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!