Product Description:

Precise Pressure Regulation and Consistent Performance

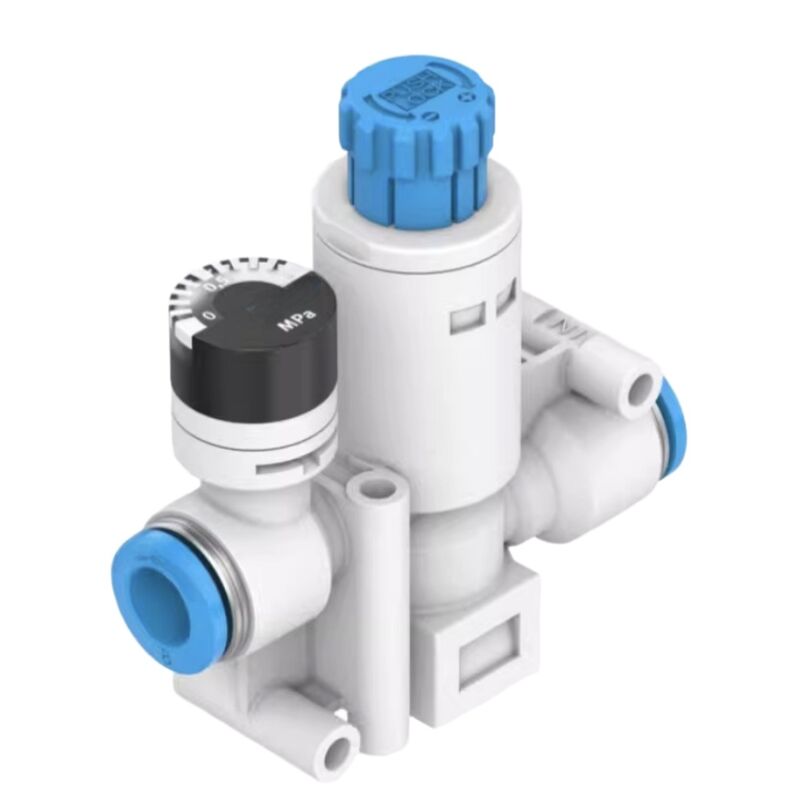

Employing a piston-type regulating mechanism, this device efficiently isolates any fluctuations in inlet pressure. This ensures that the outlet pressure remains stable at the predetermined set value. High-precision variants, such as the VRPA-CM model, deliver an exceptional regulation accuracy within ±1%, making them ideal for sensitive pneumatic applications that demand dependable pressure control.

Compact Structure with Durable Build

The series boasts a compact and space-saving design, enabling easy in-line installation directly within tubing systems or on valve manifolds. The main body is constructed from PBT engineering plastic, providing a superb combination of lightweight characteristics and robust mechanical strength. This makes the regulator both practical and long-lasting in demanding environments.

Built-in Features and Enhanced Energy Efficiency

Equipped with a secondary exhaust function, the regulator can promptly release excess downstream air whenever there is a reduction in pressure. Additionally, an integrated bypass feature allows for reverse airflow under certain conditions, thereby improving the versatility and flexibility of the entire system. By supplying pressure only as needed, this design helps to minimize compressed air consumption, resulting in significant energy savings.

Applications:

The VRPA series is highly regarded for its stability and compact design. These features make it an excellent choice across a wide range of applications.

In general industrial automation, the VRPA series plays a crucial role by delivering a stable working pressure. It is commonly used with various cylinders, small pneumatic grippers, and assembly tools. This series serves as an essential component for air preparation in automated production lines.

When it comes to precision machining and testing, the VRPA series stands out due to its high accuracy and rapid response time. These characteristics are vital for pressure-sensitive tasks such as pneumatic gauging, material testing equipment, and precision dispensing control systems.

Additionally, the compact size of the VRPA series makes it particularly suitable for environments where space is limited. It can be seamlessly integrated into equipment like industrial robot arms and modular pneumatic stations. Moreover, some models within the series are designed to meet the stringent requirements of cleanroom environments.

Support and Services:

Festo provides comprehensive technical support and services for its solenoid valve products to ensure optimal performance and customer satisfaction. Our support includes detailed product documentation, installation guides, troubleshooting tips, and maintenance recommendations to help you get the most out of your solenoid valves.

Our technical team is equipped to assist with product selection, application advice, and resolving any operational issues you may encounter. We offer training sessions and webinars to enhance your understanding of solenoid valve technology and its integration into your systems.

In addition, Festo ensures availability of genuine spare parts and accessories to maintain the reliability and longevity of your solenoid valves. Our repair and calibration services are designed to minimize downtime and extend the service life of your equipment.

For detailed information on product specifications, software tools, and updates, please refer to the Festo website and product manuals. We are committed to providing ongoing support to help you achieve efficient and effective automation solutions.

Packing and Shipping:

The Festo Solenoid Valve is carefully packaged to ensure maximum protection during transit. Each valve is individually sealed in anti-static, moisture-resistant packaging to prevent damage from environmental factors. The product is then placed in a sturdy, cushioned box designed to absorb shocks and vibrations.

For shipping, the packaged solenoid valves are securely packed in outer cartons with clear labeling that includes product specifications, handling instructions, and safety information. All shipments comply with international shipping standards to guarantee safe delivery to your location.

We recommend inspecting the package upon arrival for any signs of damage and verifying the product against the packing list. In case of any discrepancies or damage, please contact our customer service immediately for assistance.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!